Makeup Air Systems: A Vital Component for Safe and Efficient Operations

Related Articles: Makeup Air Systems: A Vital Component for Safe and Efficient Operations

Introduction

With enthusiasm, let’s navigate through the intriguing topic related to Makeup Air Systems: A Vital Component for Safe and Efficient Operations. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

Makeup Air Systems: A Vital Component for Safe and Efficient Operations

Makeup air systems are essential for maintaining safe and comfortable environments in various industrial and commercial settings. They play a critical role in replacing air that has been exhausted from a building or process, ensuring adequate ventilation and preventing negative pressure buildup. This article delves into the intricacies of makeup air systems, exploring their operation, benefits, and applications.

Understanding Makeup Air Systems: The Mechanics of Air Replacement

A makeup air system functions as a controlled air supply that compensates for air removed from a building or specific area. This air removal, often through exhaust fans or ventilation systems, can create negative pressure if not adequately balanced. Negative pressure can lead to various issues, including:

- Infiltration of pollutants: Unwanted contaminants like dust, fumes, and gases can enter the building through gaps and cracks, compromising indoor air quality.

- Energy inefficiency: The building’s heating and cooling systems struggle to maintain comfortable temperatures when negative pressure exists, leading to increased energy consumption.

- Safety hazards: In industrial settings, negative pressure can draw hazardous materials into the workspace, posing risks to workers.

Makeup air systems effectively address these challenges by providing fresh, filtered air to replace the exhausted air. This process ensures a balanced air pressure, preventing the aforementioned problems and maintaining a safe and comfortable environment.

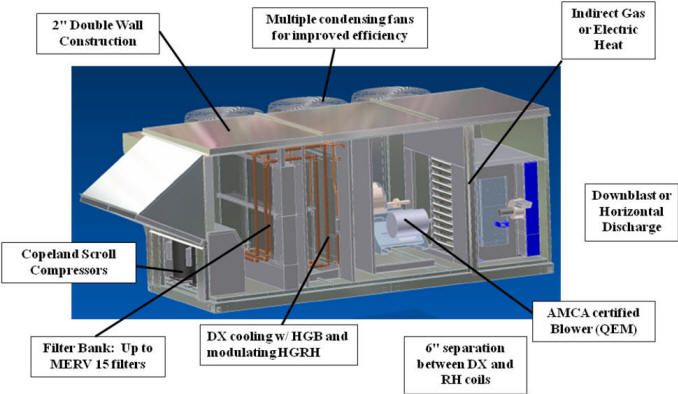

Components of a Makeup Air System: A Detailed Breakdown

A typical makeup air system comprises several key components working in harmony:

- Air intake: This component draws fresh air from the outside environment, typically through louvers or grilles.

- Filters: Filters are essential for removing contaminants like dust, pollen, and particulate matter from the incoming air. The type and efficiency of filters depend on the specific application and air quality requirements.

- Heating and cooling coils: These coils regulate the temperature of the incoming air, ensuring it is delivered at a comfortable temperature.

- Fan: The fan provides the necessary force to move the filtered and conditioned air into the building or process area.

- Control system: A control system monitors and manages the operation of the makeup air system, ensuring optimal performance and efficiency. This system may include sensors for temperature, pressure, and air quality, along with controls for adjusting fan speed, filter settings, and heating/cooling functions.

Applications of Makeup Air Systems: A Wide Range of Uses

Makeup air systems are widely employed in various industries and applications, including:

- Industrial facilities: Manufacturing plants, chemical processing facilities, and other industrial settings often use makeup air systems to control air pressure, remove hazardous fumes and dust, and maintain a safe working environment.

- Commercial buildings: Office buildings, shopping malls, and other commercial spaces utilize makeup air systems for ventilation, temperature control, and maintaining comfortable indoor air quality.

- Hospitals and healthcare facilities: Makeup air systems are crucial in hospitals and healthcare settings to provide fresh air, prevent the spread of airborne contaminants, and maintain a sterile environment.

- Data centers: Data centers rely on makeup air systems to control temperature and humidity, ensuring optimal performance and reliability of sensitive electronic equipment.

- Restaurants and kitchens: Makeup air systems are essential in kitchens to remove cooking fumes, grease, and odors, maintaining a clean and comfortable environment for staff and customers.

Benefits of Implementing a Makeup Air System: A Comprehensive Perspective

Installing a makeup air system offers numerous benefits, contributing to improved safety, comfort, and efficiency:

- Enhanced indoor air quality: By providing fresh, filtered air, makeup air systems effectively reduce the concentration of airborne pollutants, creating a healthier and more comfortable indoor environment.

- Improved worker health and productivity: Clean air and a comfortable temperature contribute to improved worker health and productivity, reducing absenteeism and increasing overall efficiency.

- Reduced energy consumption: By maintaining a balanced air pressure, makeup air systems prevent energy loss through infiltration and ensure efficient operation of heating and cooling systems.

- Increased safety: Makeup air systems effectively control air pressure, preventing the buildup of hazardous materials and reducing the risk of explosions or fires in industrial settings.

- Compliance with regulations: Many industries and jurisdictions have specific regulations regarding ventilation and air quality. Makeup air systems help businesses comply with these regulations, avoiding potential fines and legal issues.

Factors to Consider When Designing a Makeup Air System: A Practical Guide

Designing a makeup air system involves careful consideration of various factors, including:

- Building size and layout: The size and configuration of the building or process area will determine the required airflow and the number of air intake and exhaust points.

- Air quality requirements: The specific needs of the application will dictate the type and efficiency of filters required to remove contaminants from the incoming air.

- Temperature control requirements: The desired temperature range for the building or process area will determine the size and capacity of the heating and cooling coils.

- Energy efficiency considerations: The choice of fan type, filter efficiency, and control system can significantly impact the energy efficiency of the makeup air system.

- Budget constraints: The cost of the system will vary depending on its size, complexity, and the specific components used.

Frequently Asked Questions (FAQs): Addressing Common Concerns

1. How often should makeup air systems be inspected and maintained?

Regular inspection and maintenance are crucial for ensuring optimal performance and longevity of a makeup air system. Generally, it is recommended to perform inspections at least annually, with more frequent inspections required in high-use or demanding environments.

2. What are the common maintenance tasks for makeup air systems?

Common maintenance tasks include:

- Filter replacement: Filters should be replaced regularly based on their efficiency rating and the level of contamination in the incoming air.

- Fan inspection and cleaning: Inspect and clean fan blades and motor components to ensure proper operation and prevent damage.

- Heating and cooling coil inspection and cleaning: Inspect and clean coils to remove dust and debris, improving efficiency and preventing damage.

- Control system calibration: Calibrate sensors and controls to ensure accurate operation and optimal system performance.

3. What are the potential safety hazards associated with makeup air systems?

While makeup air systems are generally safe, potential hazards include:

- Electrical hazards: Proper wiring and grounding are essential to prevent electrical shocks and fires.

- Fire hazards: Filters and other components can become ignited if exposed to flammable materials.

- Mechanical hazards: Moving parts like fans and motors can pose a risk of injury if not properly guarded.

Tips for Optimizing Makeup Air System Performance: A Practical Approach

- Regularly inspect and maintain the system: This includes checking filters, fans, coils, and control systems to ensure optimal performance and prevent problems.

- Use high-quality filters: Choosing filters with appropriate efficiency ratings will ensure effective removal of contaminants and improve indoor air quality.

- Consider energy-efficient components: Opting for energy-efficient fans, filters, and control systems can reduce energy consumption and operating costs.

- Properly size the system: Ensure the system is adequately sized to meet the airflow requirements of the building or process area.

- Optimize control system settings: Adjust control system settings to optimize temperature, pressure, and air quality based on specific needs.

Conclusion: The Importance of Makeup Air Systems in Modern Buildings

Makeup air systems are essential components of modern buildings and industrial facilities, playing a vital role in maintaining safe, comfortable, and efficient environments. By providing fresh, filtered air and controlling air pressure, these systems contribute to improved indoor air quality, worker health and productivity, and energy efficiency. Understanding the operation, benefits, and design considerations of makeup air systems is crucial for creating healthy and productive spaces.

Closure

Thus, we hope this article has provided valuable insights into Makeup Air Systems: A Vital Component for Safe and Efficient Operations. We hope you find this article informative and beneficial. See you in our next article!