The Vital Role of Makeup Air in Industrial Ventilation Systems

Related Articles: The Vital Role of Makeup Air in Industrial Ventilation Systems

Introduction

With enthusiasm, let’s navigate through the intriguing topic related to The Vital Role of Makeup Air in Industrial Ventilation Systems. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

- 1 Related Articles: The Vital Role of Makeup Air in Industrial Ventilation Systems

- 2 Introduction

- 3 The Vital Role of Makeup Air in Industrial Ventilation Systems

- 3.1 Understanding Makeup Air: A Comprehensive Overview

- 3.2 Types of Makeup Air Systems

- 3.3 Key Components of a Makeup Air System

- 3.4 Designing and Implementing a Makeup Air System

- 3.5 Maintaining and Troubleshooting Makeup Air Systems

- 3.6 FAQs about Makeup Air Systems

- 3.7 Tips for Optimizing Makeup Air System Performance

- 3.8 Conclusion

- 4 Closure

The Vital Role of Makeup Air in Industrial Ventilation Systems

In the world of industrial operations, maintaining a safe and productive environment is paramount. This often necessitates the use of sophisticated ventilation systems, and within these systems, a critical component emerges: makeup air. Makeup air plays a crucial role in ensuring the efficient and safe operation of industrial processes, particularly in environments that rely on negative pressure for proper ventilation.

Understanding Makeup Air: A Comprehensive Overview

Makeup air, in its simplest definition, is fresh air that is introduced into a building or industrial space to compensate for air that is being removed by an exhaust system. This process ensures that the building maintains a balanced air pressure, preventing the buildup of contaminants and ensuring adequate airflow.

The Importance of Balanced Air Pressure

Negative pressure ventilation systems are commonly employed in industrial settings where hazardous materials, fumes, or dust are present. These systems operate by drawing air out of the workspace, creating a slight negative pressure that prevents the escape of contaminants into the surrounding environment. However, this removal of air can lead to a reduction in overall air pressure within the building, potentially causing issues like:

- Infiltration of Outside Air: Negative pressure can draw in unfiltered air from outside, introducing contaminants and compromising the integrity of the controlled environment.

- Reduced Airflow: Insufficient air pressure can hinder the effectiveness of the exhaust system, leading to poor ventilation and potential health risks.

- Energy Inefficiency: Unbalanced air pressure can create drafts, leading to increased heating and cooling costs.

Makeup Air: The Solution to Maintaining Balance

Makeup air systems address these challenges by introducing fresh, filtered air into the building to compensate for the air being removed by the exhaust system. This process ensures that the building maintains a balanced air pressure, preventing the negative consequences of excessive negative pressure.

Benefits of Makeup Air Systems

The implementation of makeup air systems provides numerous benefits for industrial operations, including:

- Enhanced Safety: Makeup air systems prevent the infiltration of outside air, ensuring a cleaner and safer working environment by minimizing the presence of contaminants.

- Improved Ventilation: By maintaining a balanced air pressure, makeup air systems ensure the efficient operation of exhaust systems, promoting proper ventilation and reducing the risk of hazardous buildup.

- Increased Productivity: A comfortable and safe working environment fostered by makeup air systems can lead to improved worker morale and productivity.

- Energy Savings: By minimizing drafts and ensuring optimal ventilation, makeup air systems can reduce heating and cooling costs, contributing to overall energy efficiency.

- Compliance with Regulations: Many industrial sectors have strict regulations regarding air quality and ventilation. Makeup air systems help businesses comply with these regulations, minimizing the risk of fines and penalties.

Types of Makeup Air Systems

Makeup air systems can be categorized based on their design and function:

1. Direct-Fired Makeup Air Units: These units use a combustion process to heat the incoming fresh air, providing both heating and ventilation. They are typically used in applications where a significant amount of heat is required, such as industrial manufacturing facilities.

2. Indirect-Fired Makeup Air Units: These units heat the incoming air indirectly through a heat exchanger, minimizing the risk of combustion byproducts entering the workspace. They are suitable for applications where a high level of air purity is required, such as pharmaceutical manufacturing.

3. Electric Makeup Air Units: These units utilize electric heating elements to warm the incoming air. They are often used in smaller applications or when energy efficiency is a primary concern.

4. Variable Air Volume (VAV) Makeup Air Systems: These systems adjust the volume of makeup air delivered based on the needs of the workspace. This allows for greater energy efficiency and precise control of the ventilation environment.

5. Demand-Controlled Ventilation (DCV) Makeup Air Systems: These systems automatically adjust the volume of makeup air based on factors like temperature, humidity, and air quality. This provides a highly efficient and responsive ventilation system.

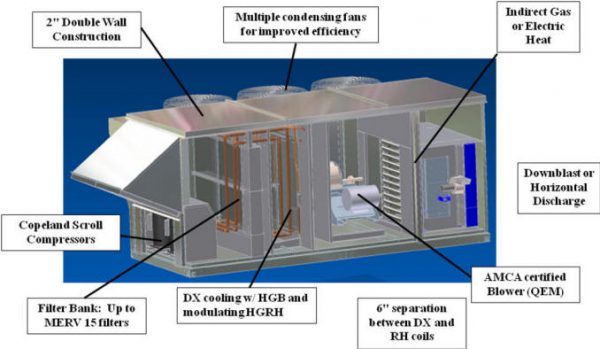

Key Components of a Makeup Air System

A typical makeup air system comprises several essential components:

- Air Intake: The air intake is the point where fresh air enters the system. It is typically equipped with filters to remove dust, debris, and other contaminants from the incoming air.

- Fan: The fan is responsible for drawing fresh air into the system and pushing it through the filters and heating or cooling elements.

- Heating or Cooling Element: Depending on the application, the system may include a heating element (for winter conditions) or a cooling element (for summer conditions) to regulate the temperature of the makeup air.

- Filter: The filter removes contaminants from the incoming air, ensuring that only clean and fresh air is delivered to the workspace.

- Control System: The control system manages the operation of the makeup air system, adjusting airflow, temperature, and other parameters as needed.

Designing and Implementing a Makeup Air System

The design and implementation of a makeup air system require careful consideration of several factors:

- Space Requirements: The size and layout of the workspace will determine the capacity and configuration of the makeup air system.

- Airflow Needs: The amount of air that needs to be introduced to maintain a balanced air pressure will depend on the size of the workspace, the ventilation rate, and the type of exhaust system used.

- Temperature Requirements: The desired temperature of the makeup air will vary depending on the climate and the specific needs of the workspace.

- Air Quality Requirements: The level of air purity required will influence the type of filters used and the overall design of the system.

- Energy Efficiency: The energy efficiency of the makeup air system is a critical consideration, particularly in light of rising energy costs.

Factors Affecting Makeup Air System Design

Several factors influence the design and implementation of a makeup air system:

- Type of Industrial Process: The specific industrial process being conducted will determine the type of contaminants that need to be removed and the required ventilation rate.

- Building Design: The layout and structure of the building will impact the placement and configuration of the makeup air system.

- Environmental Regulations: Local and national regulations regarding air quality and ventilation will need to be considered during the design process.

- Budget: The budget available for the project will influence the materials, components, and overall design of the makeup air system.

Maintaining and Troubleshooting Makeup Air Systems

Once a makeup air system is installed, regular maintenance is essential to ensure its optimal performance and longevity. This includes:

- Filter Replacement: Filters should be inspected and replaced regularly to maintain air quality and prevent the buildup of contaminants.

- Fan Inspection: The fan should be inspected for wear and tear, and its lubrication should be maintained.

- Control System Calibration: The control system should be calibrated regularly to ensure that it is operating accurately and efficiently.

- Performance Monitoring: The performance of the makeup air system should be monitored regularly to identify any issues that may need to be addressed.

Troubleshooting Common Issues:

- Low Airflow: A low airflow rate can indicate a clogged filter, a malfunctioning fan, or a problem with the control system.

- Excessive Noise: Loud noises from the makeup air system could be caused by a worn-out fan, loose components, or improper installation.

- Uneven Temperature Distribution: Uneven temperature distribution may indicate a problem with the heating or cooling element, a blockage in the ductwork, or an issue with the control system.

FAQs about Makeup Air Systems

1. What is the purpose of makeup air?

The purpose of makeup air is to introduce fresh, filtered air into a building or industrial space to compensate for air that is being removed by an exhaust system. This maintains a balanced air pressure, preventing the buildup of contaminants and ensuring adequate airflow.

2. Why is makeup air important?

Makeup air is crucial for maintaining a safe and productive working environment in industrial settings. It prevents the infiltration of outside air, ensures proper ventilation, and helps comply with environmental regulations.

3. How does a makeup air system work?

A makeup air system draws fresh air from outside, filters it to remove contaminants, and then delivers it into the workspace. The system may also include heating or cooling elements to regulate the temperature of the air.

4. What are the different types of makeup air systems?

Makeup air systems can be direct-fired, indirect-fired, electric, VAV, or DCV, each with its own advantages and disadvantages.

5. How often should makeup air filters be changed?

The frequency of filter replacement depends on the type of filter, the level of contamination in the air, and the operating conditions. However, it is generally recommended to inspect and replace filters at least every three months.

6. What are the signs of a malfunctioning makeup air system?

Signs of a malfunctioning makeup air system include low airflow, excessive noise, uneven temperature distribution, and an increase in the concentration of contaminants in the workspace.

7. How can I improve the energy efficiency of my makeup air system?

Energy efficiency can be improved by using high-efficiency filters, optimizing the control system, and employing variable air volume or demand-controlled ventilation strategies.

8. What are the safety considerations for makeup air systems?

Safety considerations include proper installation, regular maintenance, and ensuring that the system is properly vented to prevent the buildup of combustion byproducts.

9. What are the costs associated with a makeup air system?

The cost of a makeup air system will vary depending on the size, complexity, and type of system. It is important to consult with a qualified HVAC contractor to get an accurate estimate.

10. How do I choose the right makeup air system for my needs?

The best makeup air system for your needs will depend on factors such as the size of the workspace, the type of industrial process being conducted, the air quality requirements, and the budget.

Tips for Optimizing Makeup Air System Performance

- Regular Maintenance: Regularly inspect and maintain all components of the makeup air system, including filters, fans, and control systems.

- Filter Selection: Choose high-quality filters that are appropriate for the type of contaminants present in the workspace.

- Control System Optimization: Optimize the control system to ensure that the makeup air system is operating efficiently and effectively.

- Ductwork Inspection: Regularly inspect ductwork for leaks, blockages, and other issues that could affect airflow.

- Energy Efficiency Measures: Implement energy-saving measures, such as using variable air volume or demand-controlled ventilation systems.

Conclusion

Makeup air systems are a vital component of industrial ventilation systems, playing a crucial role in maintaining a safe, productive, and energy-efficient working environment. By ensuring balanced air pressure and providing fresh, filtered air, makeup air systems contribute significantly to the overall health and well-being of workers and the effectiveness of industrial processes. The careful design, implementation, and maintenance of makeup air systems are essential for maximizing their benefits and minimizing potential risks.

Closure

Thus, we hope this article has provided valuable insights into The Vital Role of Makeup Air in Industrial Ventilation Systems. We hope you find this article informative and beneficial. See you in our next article!