Understanding Makeup Water Calculation for Cooling Towers: A Comprehensive Guide

Related Articles: Understanding Makeup Water Calculation for Cooling Towers: A Comprehensive Guide

Introduction

With great pleasure, we will explore the intriguing topic related to Understanding Makeup Water Calculation for Cooling Towers: A Comprehensive Guide. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

Understanding Makeup Water Calculation for Cooling Towers: A Comprehensive Guide

.png)

Cooling towers are essential components in various industrial and commercial applications, playing a vital role in regulating temperatures and ensuring optimal performance of machinery and processes. However, the continuous operation of these systems inevitably leads to water loss through evaporation, drift, and blowdown. This loss necessitates the replenishment of the cooling water circuit with fresh water, known as makeup water. Accurately calculating makeup water requirements is crucial for efficient operation, cost optimization, and environmental sustainability.

The Importance of Precise Makeup Water Calculation

Calculating makeup water needs accurately is paramount for several reasons:

- Minimizing Water Consumption and Costs: Overestimating makeup water requirements leads to unnecessary water usage, increasing operational expenses and putting strain on water resources. Conversely, underestimating makeup water can result in insufficient cooling capacity, leading to equipment damage and operational disruptions.

- Optimizing Cooling Tower Performance: Maintaining the appropriate water level in the cooling tower is crucial for efficient heat transfer and cooling. Insufficient makeup water can lead to reduced cooling capacity, while excessive makeup water can dilute the concentration of chemicals used for water treatment, compromising cooling tower performance.

- Environmental Sustainability: Cooling towers are significant water users. Precise makeup water calculations minimize water consumption, promoting responsible water management and reducing the environmental impact of industrial operations.

- Chemical Treatment Optimization: Accurate makeup water calculations allow for precise adjustments in chemical treatment dosages, ensuring effective water treatment without overdosing and reducing chemical costs.

Factors Influencing Makeup Water Requirements

Several factors influence the makeup water requirements for a cooling tower, including:

- Cooling Tower Design and Size: The size and design of the cooling tower, including the surface area of the fill and the airflow rate, directly impact evaporation rates and, consequently, makeup water needs.

- Climate Conditions: Ambient temperature, humidity, and wind speed significantly influence evaporation rates. High temperatures and low humidity result in higher evaporation and, therefore, increased makeup water requirements.

- Water Quality: The quality of the makeup water influences the frequency of blowdown, which is the process of removing concentrated impurities from the cooling water circuit. Water with higher mineral content requires more frequent blowdown, increasing makeup water needs.

- Cooling Water Load: The heat load imposed on the cooling water determines the amount of water circulated and, consequently, the evaporation rate. Higher heat loads lead to increased evaporation and higher makeup water requirements.

- Operating Conditions: Factors like operating hours, cooling water temperature setpoints, and the frequency of cleaning and maintenance can also affect makeup water requirements.

Methods for Calculating Makeup Water Requirements

Several methods can be used to calculate makeup water requirements for cooling towers:

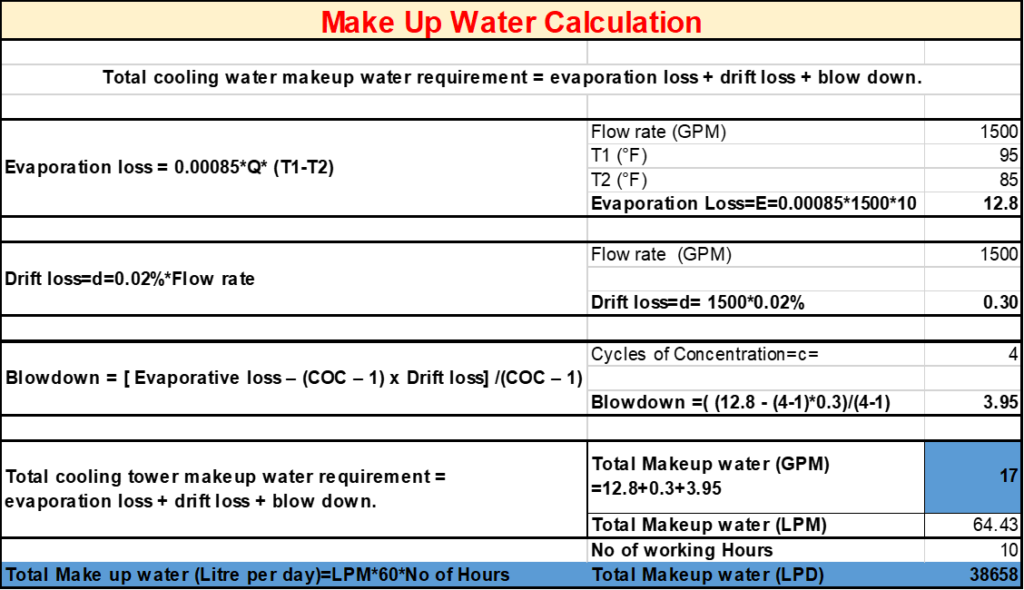

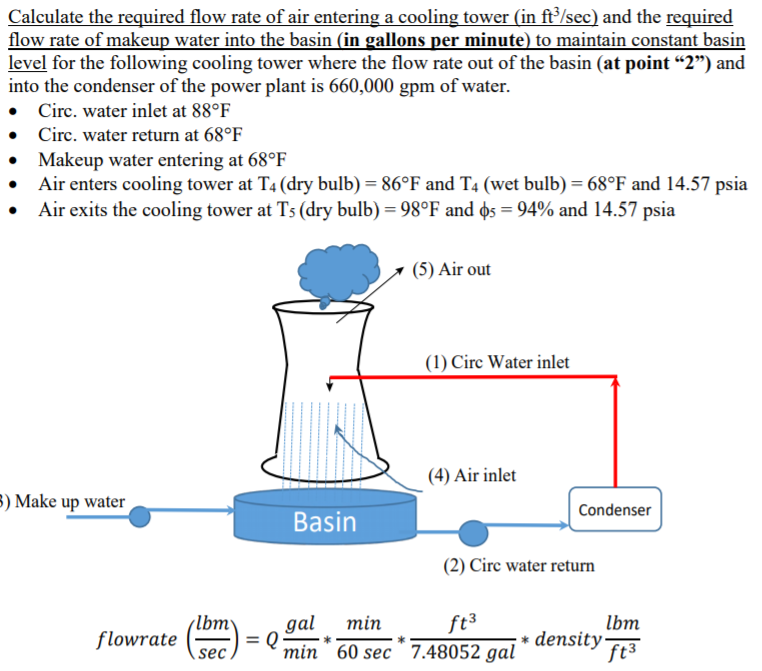

1. Evaporation Rate Method:

This method relies on estimating the evaporation rate based on the cooling tower’s design parameters, operating conditions, and climate data. The formula for calculating makeup water using the evaporation rate method is:

Makeup Water (m3/hr) = Evaporation Rate (m3/hr) / (1 – Blowdown Rate)

Where:

- Evaporation Rate: The amount of water lost through evaporation per unit time.

- Blowdown Rate: The percentage of cooling water removed through blowdown to control water quality.

2. Water Balance Method:

This method involves tracking the water added to the cooling tower and the water removed from the system. The difference between these two represents the makeup water requirement. The formula for calculating makeup water using the water balance method is:

Makeup Water (m3/hr) = Water Added (m3/hr) – Water Removed (m3/hr)

Where:

- Water Added: The total amount of water added to the cooling tower, including makeup water and any other sources.

- Water Removed: The total amount of water removed from the cooling tower, including blowdown, drift, and any other losses.

3. Empirical Formulas:

Several empirical formulas are available for calculating makeup water requirements based on specific cooling tower types and operating conditions. These formulas often consider factors like cooling water temperature, air temperature, and wind speed.

4. Computer Simulation Software:

Sophisticated computer simulation software can accurately model cooling tower performance and predict makeup water requirements based on detailed design parameters, operating conditions, and climate data. These tools provide valuable insights into optimization strategies and can help minimize water consumption.

Determining the Appropriate Method:

The choice of method for calculating makeup water requirements depends on the specific application, available data, and desired level of accuracy. For initial estimations, the evaporation rate method or empirical formulas can be sufficient. However, for precise calculations and optimization, the water balance method or computer simulation software is recommended.

Optimizing Makeup Water Calculation for Enhanced Efficiency

Several strategies can be employed to optimize makeup water calculations and minimize water consumption:

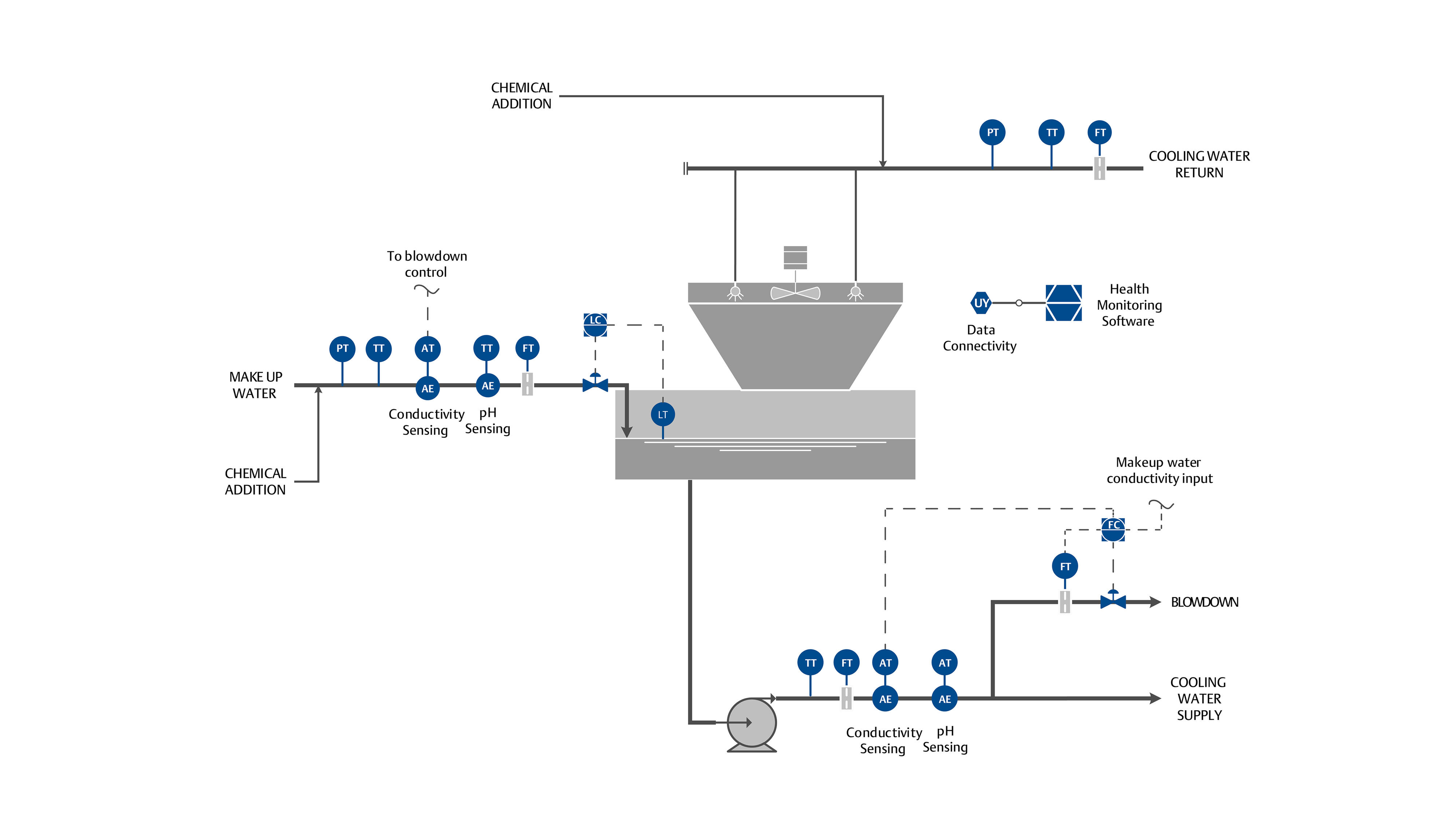

- Regular Monitoring and Data Collection: Continuously monitoring water levels, flow rates, and operating conditions provides valuable data for refining makeup water calculations.

- Accurate Measurement of Water Losses: Employing reliable methods for measuring evaporation, drift, and blowdown ensures accurate accounting of water losses and precise makeup water requirements.

- Regular Maintenance and Cleaning: Regularly cleaning and maintaining the cooling tower minimizes water losses due to leaks, corrosion, or fouling.

- Water Conservation Technologies: Implementing water conservation technologies, such as low-drift nozzles, advanced water treatment systems, and closed-loop cooling systems, can significantly reduce makeup water requirements.

- Optimization of Blowdown Rates: Adjusting blowdown rates based on water quality and operating conditions can optimize water conservation without compromising cooling tower performance.

- Utilizing Water Recycling Systems: Implementing water recycling systems can recover and reuse blowdown water, reducing the need for fresh makeup water.

FAQs on Makeup Water Calculation for Cooling Towers

Q: What is the typical makeup water requirement for a cooling tower?

A: The makeup water requirement varies significantly based on factors like cooling tower size, operating conditions, and climate. However, a general estimate is around 1-5% of the cooling water flow rate.

Q: How often should I adjust my makeup water calculation?

A: It is recommended to review and adjust your makeup water calculation at least annually, or more frequently if significant changes occur in operating conditions, water quality, or climate.

Q: Can I use treated wastewater as makeup water for my cooling tower?

A: Yes, treated wastewater can be used as makeup water for cooling towers, provided it meets specific quality standards and is compatible with the cooling tower’s materials and operating conditions.

Q: What are the consequences of overestimating makeup water requirements?

A: Overestimating makeup water requirements leads to unnecessary water consumption, increased operational costs, and potential environmental impacts.

Q: What are the consequences of underestimating makeup water requirements?

A: Underestimating makeup water requirements can lead to insufficient cooling capacity, equipment damage, operational disruptions, and potential safety hazards.

Conclusion

Accurate makeup water calculation is essential for efficient and sustainable operation of cooling towers. By understanding the factors influencing makeup water requirements and employing appropriate calculation methods, operators can optimize water consumption, reduce operational costs, and minimize environmental impacts. Continuous monitoring, regular maintenance, and the implementation of water conservation technologies are crucial for achieving optimal makeup water management and maximizing the efficiency of cooling tower systems.

Closure

Thus, we hope this article has provided valuable insights into Understanding Makeup Water Calculation for Cooling Towers: A Comprehensive Guide. We hope you find this article informative and beneficial. See you in our next article!