Understanding the Crucial Role of Make-Up Water in Cooling Tower Operations

Related Articles: Understanding the Crucial Role of Make-Up Water in Cooling Tower Operations

Introduction

With enthusiasm, let’s navigate through the intriguing topic related to Understanding the Crucial Role of Make-Up Water in Cooling Tower Operations. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

Understanding the Crucial Role of Make-Up Water in Cooling Tower Operations

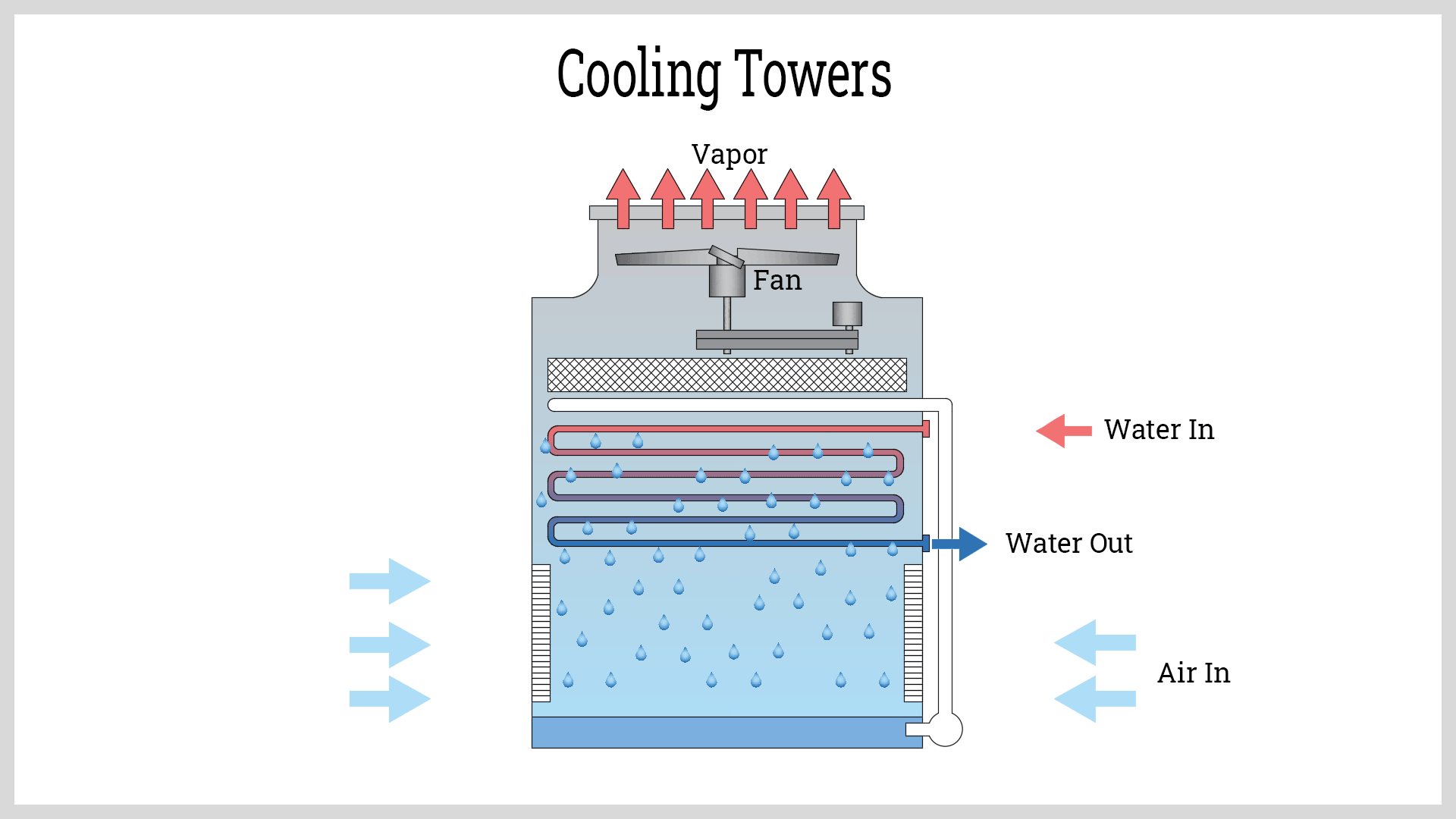

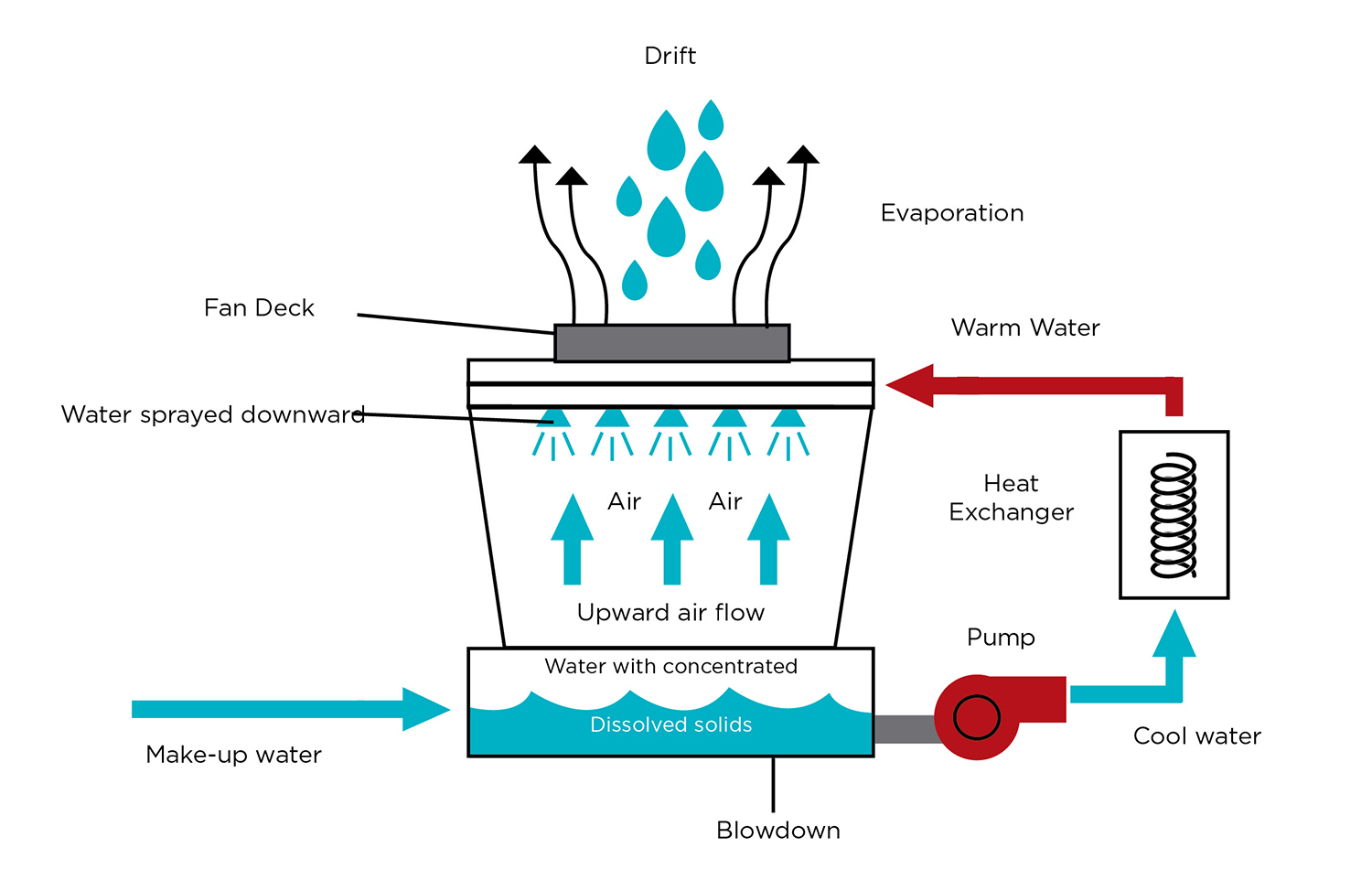

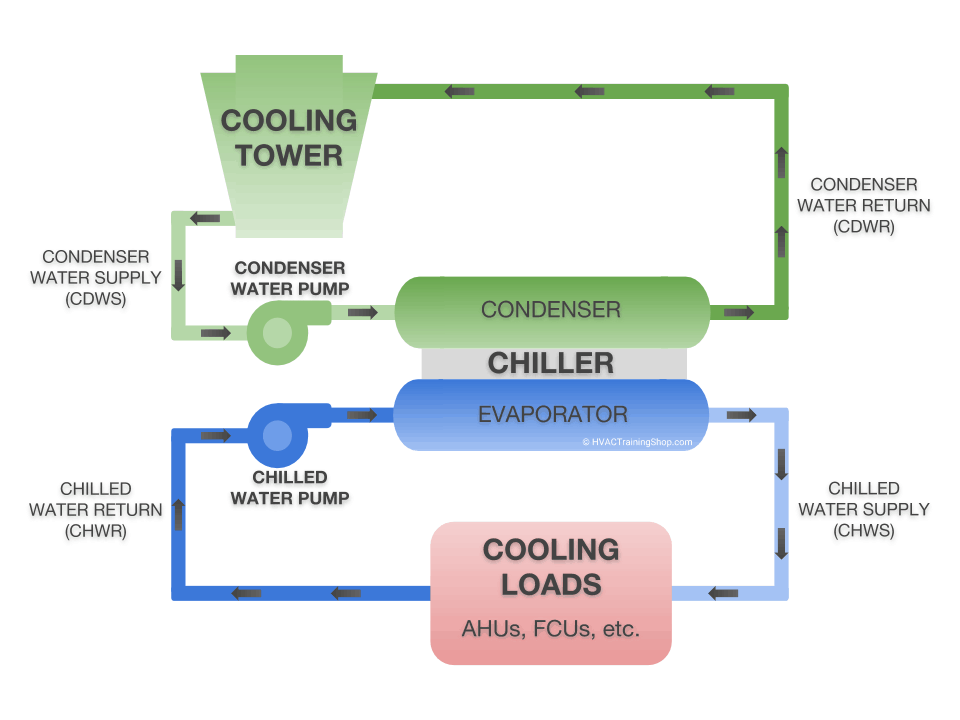

Cooling towers are essential components in various industrial and commercial applications, playing a critical role in maintaining optimal temperatures for processes and equipment. Their functionality relies heavily on the continuous circulation of water, which absorbs heat from the system and releases it into the atmosphere through evaporation. However, this process inevitably leads to water loss through evaporation and drift, necessitating the constant replenishment of the cooling water system. This replenishment is achieved through the addition of "make-up water," a vital aspect of cooling tower operation.

The Importance of Make-Up Water

Make-up water is not just a simple replacement for lost water; it plays a critical role in ensuring the efficient and reliable operation of cooling towers. Its importance can be understood through its multifaceted impact on:

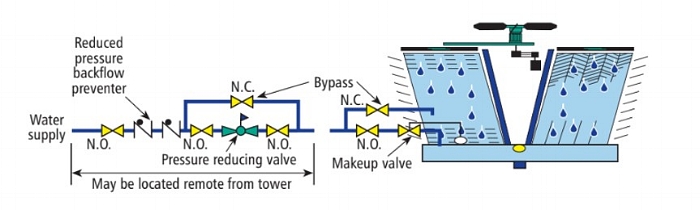

- Maintaining Water Levels: The continuous evaporation of water in the cooling tower necessitates constant replenishment to maintain appropriate water levels. Without adequate make-up water, the tower’s performance would be compromised, leading to reduced cooling capacity and potential damage to equipment.

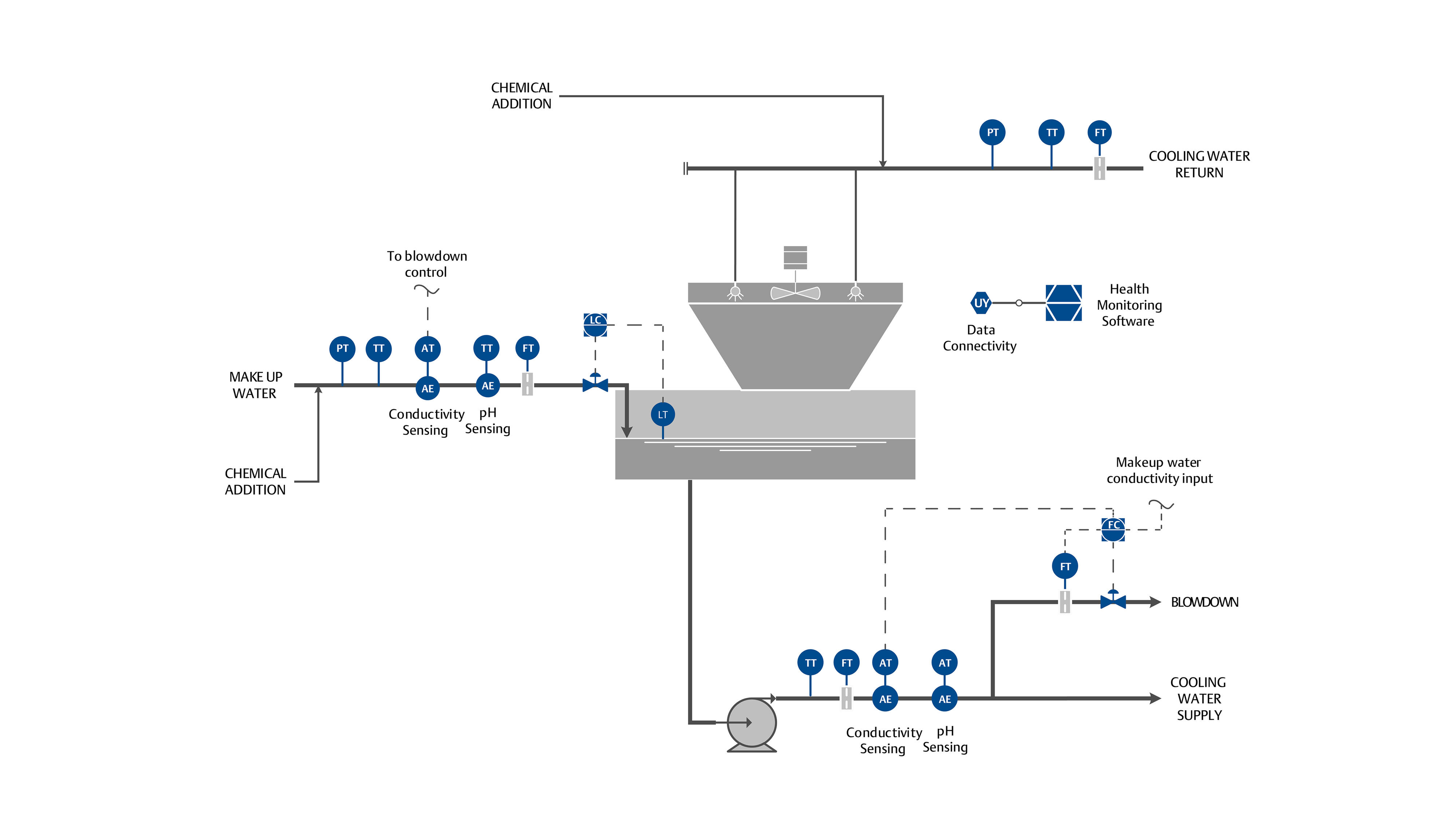

- Preventing System Concentration: As water evaporates, dissolved solids and impurities in the cooling water become concentrated, potentially leading to scaling, corrosion, and fouling. Make-up water dilutes these concentrations, preventing these detrimental effects and ensuring the longevity of the cooling tower system.

- Controlling Water Chemistry: The quality of make-up water directly influences the chemical balance of the cooling water. By adding treated make-up water, the chemical composition of the cooling water can be controlled, optimizing its performance and preventing corrosion, scaling, and microbial growth.

- Maintaining Cooling Efficiency: The quality and quantity of make-up water directly impact the cooling tower’s efficiency. Impurities in make-up water can lead to fouling and scaling, reducing heat transfer and hindering the tower’s ability to effectively dissipate heat.

Factors Influencing Make-Up Water Requirements

The volume of make-up water required for a cooling tower is influenced by several factors, including:

- Climate: Hot and dry climates experience higher evaporation rates, leading to increased make-up water requirements.

- Cooling Tower Design: The design of the cooling tower, including its size and type, influences the rate of water loss and, consequently, the volume of make-up water needed.

- Operating Conditions: The operating load of the cooling tower, including the temperature difference between the cooling water and the air, influences the evaporation rate and, therefore, the make-up water demand.

- Water Quality: The quality of the source water significantly impacts the required make-up water volume. High levels of impurities necessitate more frequent and larger make-up water additions to maintain water quality and prevent system problems.

Treating Make-Up Water for Optimal Performance

The quality of make-up water is paramount to the efficient and reliable operation of a cooling tower. Raw water often contains impurities that can lead to various issues within the system, including:

- Scaling: Hard water containing high levels of calcium and magnesium can form scale deposits on heat transfer surfaces, reducing cooling efficiency.

- Corrosion: Dissolved gases like oxygen and carbon dioxide can promote corrosion of metal components within the cooling tower system.

- Fouling: Organic matter and suspended solids in the water can accumulate on heat transfer surfaces, hindering heat transfer and reducing efficiency.

- Microbial Growth: Microorganisms can thrive in cooling water, leading to biofouling, corrosion, and the potential for health hazards.

To address these concerns, make-up water is typically treated before being added to the cooling tower. Common treatment methods include:

- Filtration: Removes suspended solids and particulate matter.

- Softening: Reduces the concentration of calcium and magnesium, preventing scaling.

- Corrosion Inhibition: Adds chemicals to prevent corrosion of metal components.

- Disinfection: Eliminates microorganisms to prevent biofouling and health risks.

Choosing the Right Make-Up Water Treatment

Selecting the appropriate make-up water treatment method depends on several factors, including:

- Source Water Quality: The specific impurities present in the source water dictate the necessary treatment methods.

- Cooling Tower Design: The type and size of the cooling tower influence the required water quality and the treatment method needed.

- Operating Conditions: The operating load and temperature difference within the cooling tower impact the potential for scaling, corrosion, and fouling, influencing the treatment approach.

- Cost and Efficiency: The cost-effectiveness and efficiency of different treatment methods should be considered.

FAQs about Make-Up Water in Cooling Towers

1. What are the consequences of using untreated make-up water?

Using untreated make-up water can lead to various issues, including:

- Scaling: Deposits on heat transfer surfaces, reducing cooling efficiency.

- Corrosion: Damage to metal components within the system.

- Fouling: Accumulation of organic matter and suspended solids, hindering heat transfer.

- Microbial Growth: Biofouling, corrosion, and potential health hazards.

2. What are the common methods for treating make-up water?

Common treatment methods include:

- Filtration: Removes suspended solids and particulate matter.

- Softening: Reduces the concentration of calcium and magnesium, preventing scaling.

- Corrosion Inhibition: Adds chemicals to prevent corrosion of metal components.

- Disinfection: Eliminates microorganisms to prevent biofouling and health risks.

3. How often should make-up water be tested?

The frequency of make-up water testing depends on factors such as the source water quality, the operating conditions of the cooling tower, and the treatment method employed. However, regular testing is essential to ensure that the water quality remains within acceptable limits and that the treatment system is functioning effectively.

4. What are the potential environmental impacts of make-up water?

The environmental impact of make-up water depends on the source of the water and the treatment methods employed. For example, using water from a municipal source may involve the use of chemicals for treatment, which could have environmental consequences. It is important to consider the environmental impact of make-up water and choose treatment methods that minimize these effects.

5. How can I reduce my cooling tower’s make-up water requirements?

Several strategies can help reduce make-up water requirements:

- Optimize Operating Conditions: Adjusting the operating load and temperature difference can reduce evaporation rates and minimize water loss.

- Improve Water Conservation: Implementing measures to reduce water loss through leaks and spills can significantly decrease make-up water demand.

- Utilize Water Recycling Systems: Recycling treated blowdown water back into the cooling tower can reduce the need for fresh make-up water.

- Consider Alternative Cooling Technologies: Exploring alternative cooling technologies, such as dry cooling towers, can eliminate or significantly reduce the need for make-up water.

Tips for Managing Make-Up Water in Cooling Towers

- Regularly monitor and test make-up water quality. This ensures that the treatment system is effectively removing impurities and that the water quality remains within acceptable limits.

- Implement a preventive maintenance program for the cooling tower and treatment system. This helps prevent problems and ensures optimal performance.

- Use high-quality chemicals for treatment. This minimizes the potential for environmental impact and ensures effective treatment.

- Consider using alternative cooling technologies. Exploring options like dry cooling towers can reduce or eliminate the need for make-up water.

- Stay informed about best practices for managing make-up water. Consult with industry experts and keep up-to-date on advancements in cooling tower technology and water treatment.

Conclusion

Make-up water is a critical component of cooling tower operation, playing a vital role in maintaining water levels, preventing system concentration, controlling water chemistry, and ensuring optimal cooling efficiency. Understanding the importance of make-up water and implementing effective treatment strategies are essential for maximizing cooling tower performance, minimizing operational costs, and ensuring the longevity of the system. By addressing the factors influencing make-up water requirements and employing appropriate treatment methods, cooling tower operators can ensure reliable and efficient operation, minimizing environmental impact and maximizing the lifespan of their cooling systems.

Closure

Thus, we hope this article has provided valuable insights into Understanding the Crucial Role of Make-Up Water in Cooling Tower Operations. We hope you find this article informative and beneficial. See you in our next article!